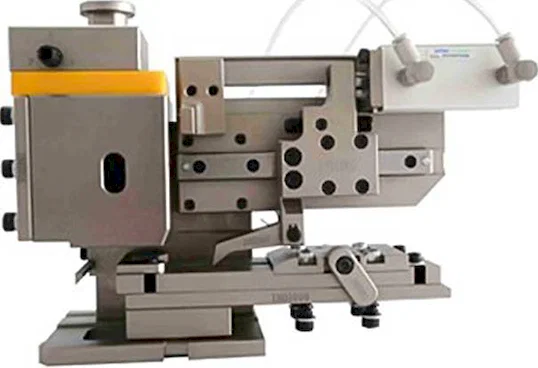

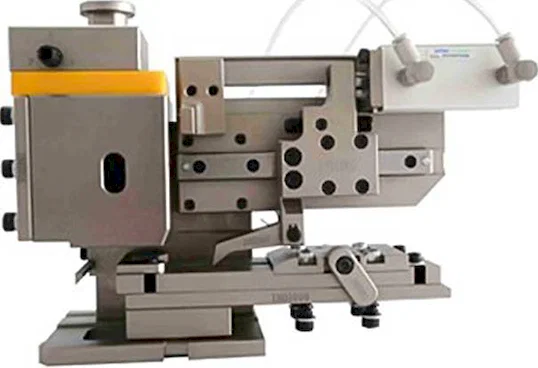

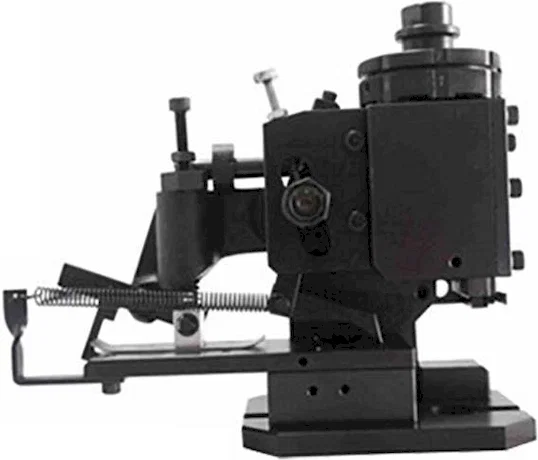

OTP Transverse Mold: Precision and Efficiency in Transverse Tape Wrapping

Elevate

your transverse tape wrapping operations with our custom-engineered OTP

Transverse Molds. Designed for seamless integration with your tape

wrapping machinery, these molds are the key to achieving precise,

consistent, and high-quality tape application on a wide range of

products, including wire harnesses, cables, pipes, and rods.

Our

OTP Transverse Molds are not off-the-shelf components; they are

meticulously designed and manufactured to meet your specific application

requirements, ensuring optimal performance and a perfect fit for your

products.

Key Features & Benefits:

-

Custom-Engineered for Your Application:

-

Benefit: Perfect Fit, Optimal Performance.

-

Each

mold is tailor-made based on your product's diameter, shape, the type

of tape used, and the desired wrapping specifications. This bespoke

approach guarantees precise tape placement and adherence every time.

-

Unparalleled Wrapping Accuracy & Consistency:

-

Benefit: Flawless Finish, Reduced Rejects.

-

The

precision design of our transverse molds ensures that tape is applied

uniformly and exactly where needed, eliminating inconsistencies,

reducing tape waste, and ensuring a tight, secure wrap.

-

Enhanced Operational Efficiency:

-

Benefit: Increased Throughput, Lower Labor Costs.

-

By

automating and perfecting the transverse taping process, our molds help

reduce cycle times, minimize manual intervention, and boost overall

productivity.

-

Superior Product Protection & Aesthetics:

-

Benefit: Improved Durability, Professional Appearance.

-

Achieve

a neat, professional, and durable tape wrap that enhances the

protection of your products against abrasion, environmental factors, and

wear, while also improving their overall appearance.

-

Robust and Long-Lasting Construction:

-

Benefit: Extended Lifespan, Reduced Downtime.

-

Crafted

from high-quality, wear-resistant materials, our transverse molds are

built to withstand the rigors of continuous industrial use. This ensures

extended operational life, minimal maintenance, and consistent

performance over time.

-

Seamless Integration & Ease of Use:

-

Benefit: Quick Setup, Minimal Disruption.

-

Designed

for easy installation and compatibility with a variety of tape wrapping

machines, our molds allow for quick changeovers and minimal disruption

to your production line.

-

Versatility in Application:

-

Benefit: Adaptable to Diverse Needs.

-

Suitable

for various tape materials (e.g., PVC, cloth, foam) and a wide array of

product profiles, providing a flexible solution for your transverse

taping needs.

How Our Custom OTP Transverse Molds Work:

The

OTP Transverse Mold acts as a precise guide and forming tool during the

tape wrapping process. As your product (e.g., a wire harness) passes

through the wrapping head, the mold ensures that the tape is applied

transversely (around the circumference) with the correct tension,

overlap, and positioning. Its custom shape conforms to your product,

ensuring that even complex profiles or varying diameters (within a

specified range for a given mold) are wrapped effectively.

Applications:

Our OTP Transverse Molds are ideal for industries and applications requiring high-quality transverse tape wrapping, including:

-

Automotive: Wire harnesses, cable assemblies, fluid pipes.

-

Electronics: Cable management, component bundling.

-

Aerospace: Specialized wiring and tubing.

-

Industrial Manufacturing: Hoses, pipes, rods, and other cylindrical or elongated components.

-

Appliance Manufacturing: Internal wiring and tubing.

Why Choose Our OTP Transverse Molds?

-

Expert Design: Leveraging years of experience in tape wrapping technology.

-

Precision Manufacturing: Ensuring the highest quality and dimensional accuracy.

-

Tailored Solutions: We work closely with you to understand your unique requirements.

-

Performance Driven: Focused on improving your quality, efficiency, and bottom line.

-

Dedicated Support: Our team is here to assist you from initial consultation to post-installation.